Center Line Technology

STAMPING PROCESS (LIP)

Fortified by a deep-drawn stamping process, the lip of our wheel achieves exceptional strength. This technique cold-works the metal, densifying it and creating a robust rim that can handle even the toughest conditions.

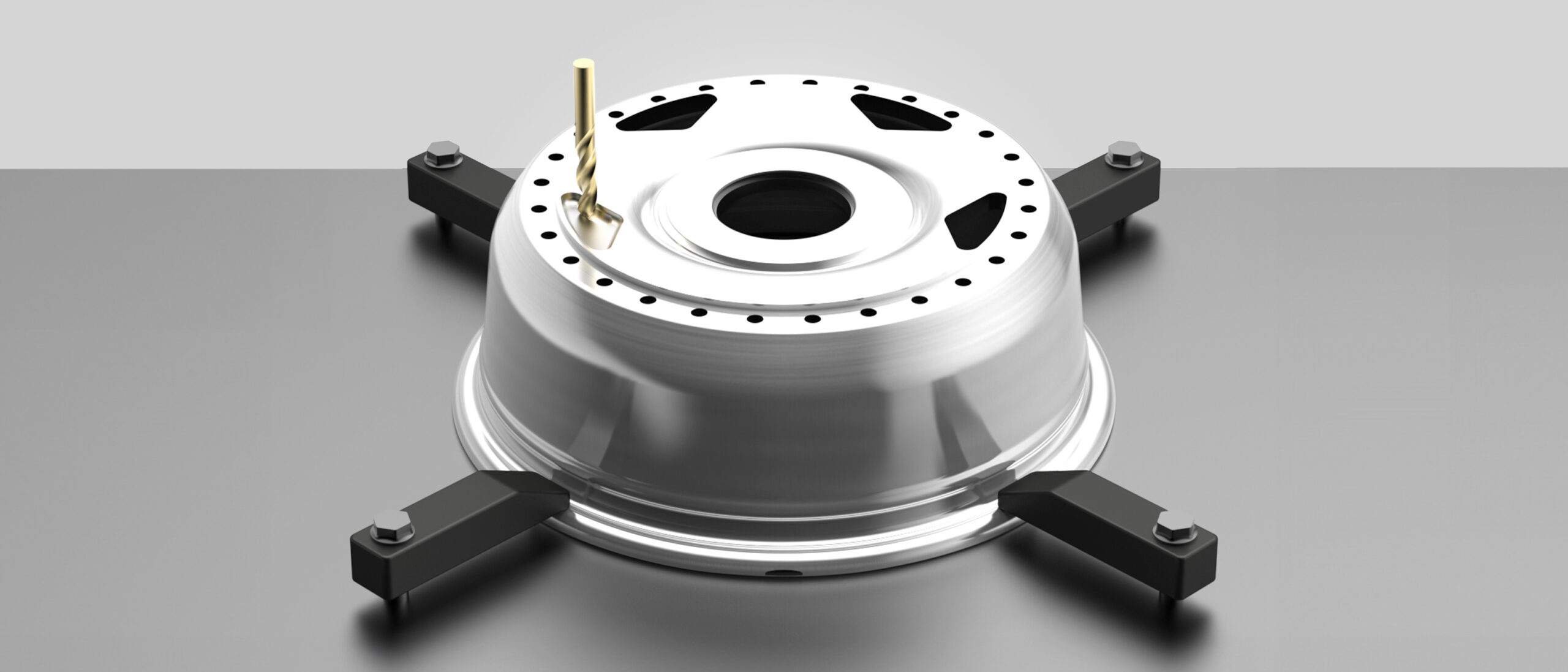

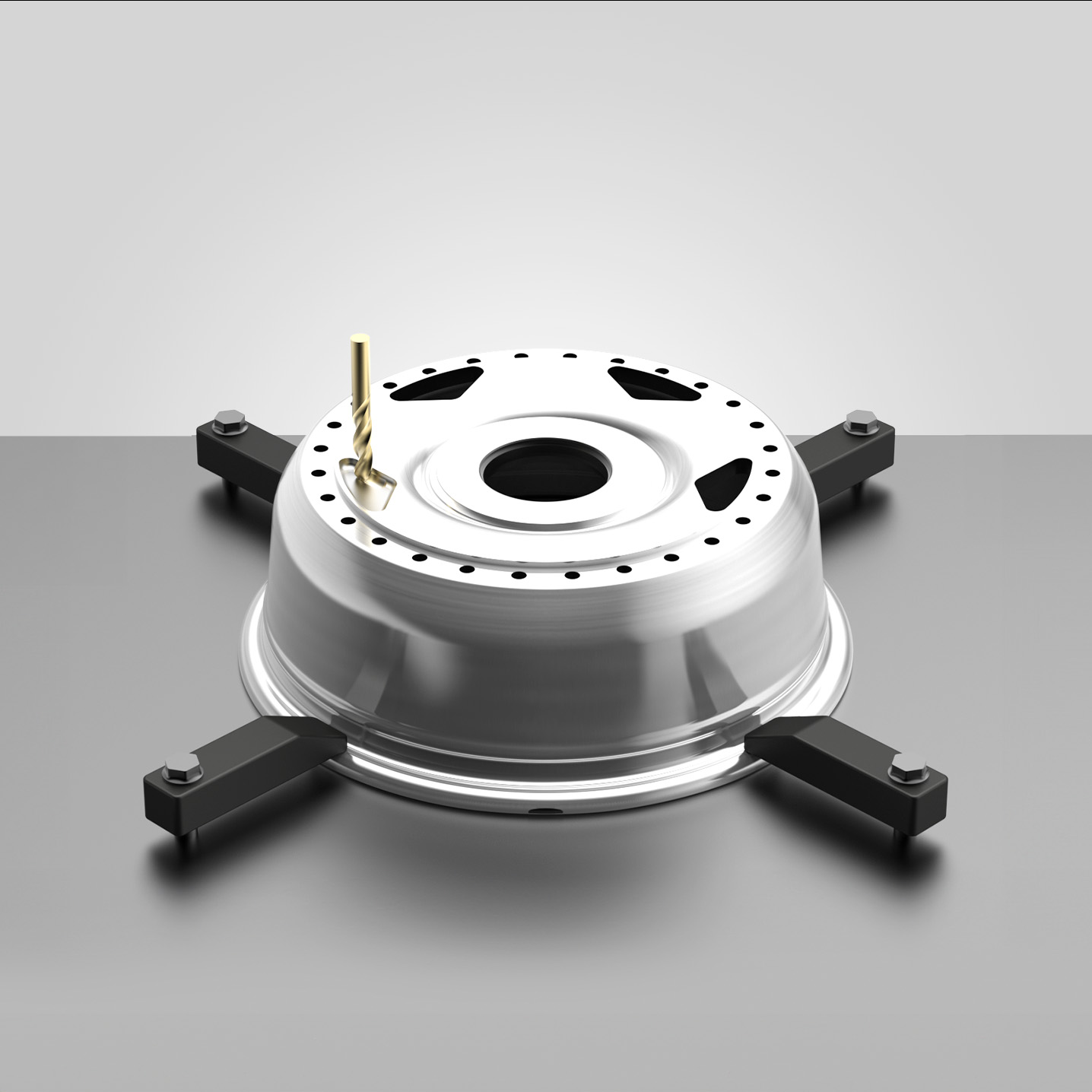

MILLING PROCESS (FACE)

Our wheels benefit from a precision milling process that meticulously removes excess material. This computer-controlled sculpting ensures an incredibly strong and lightweight design, optimizing performance without sacrificing durability.

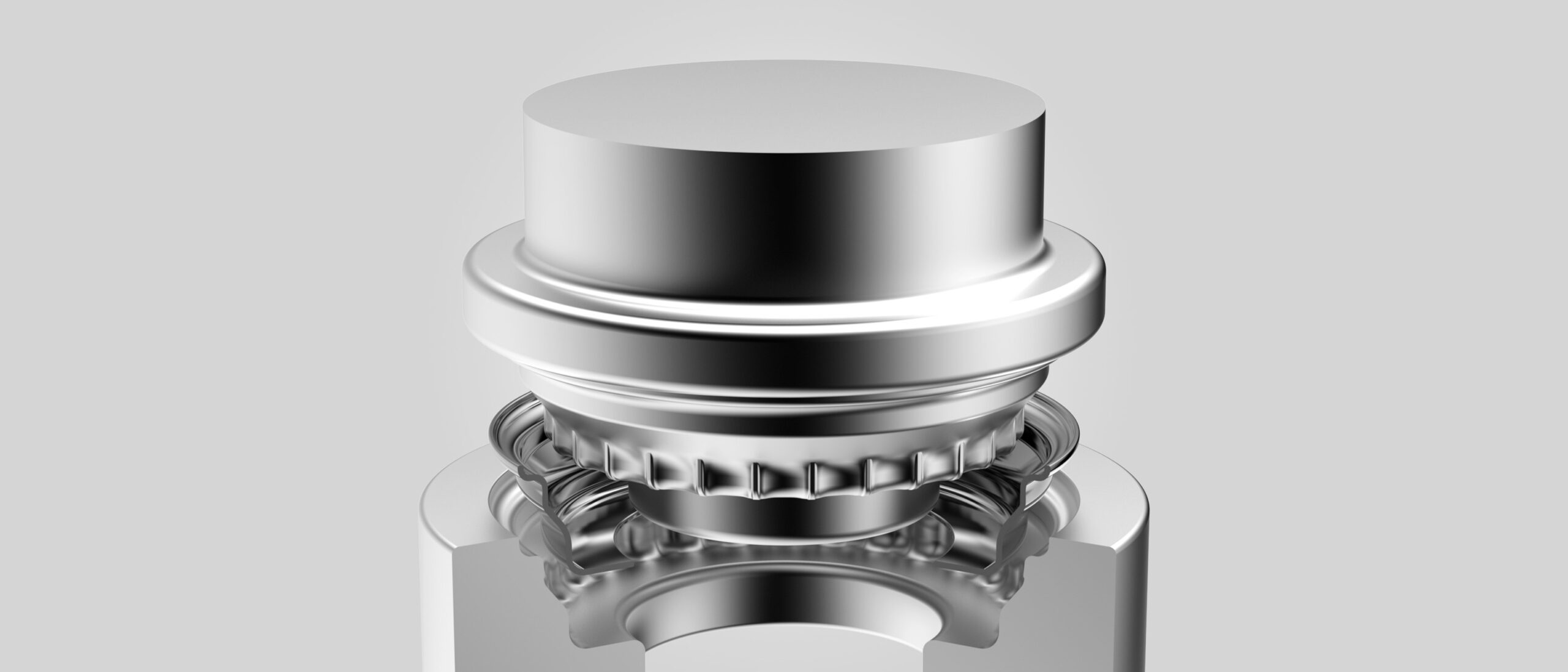

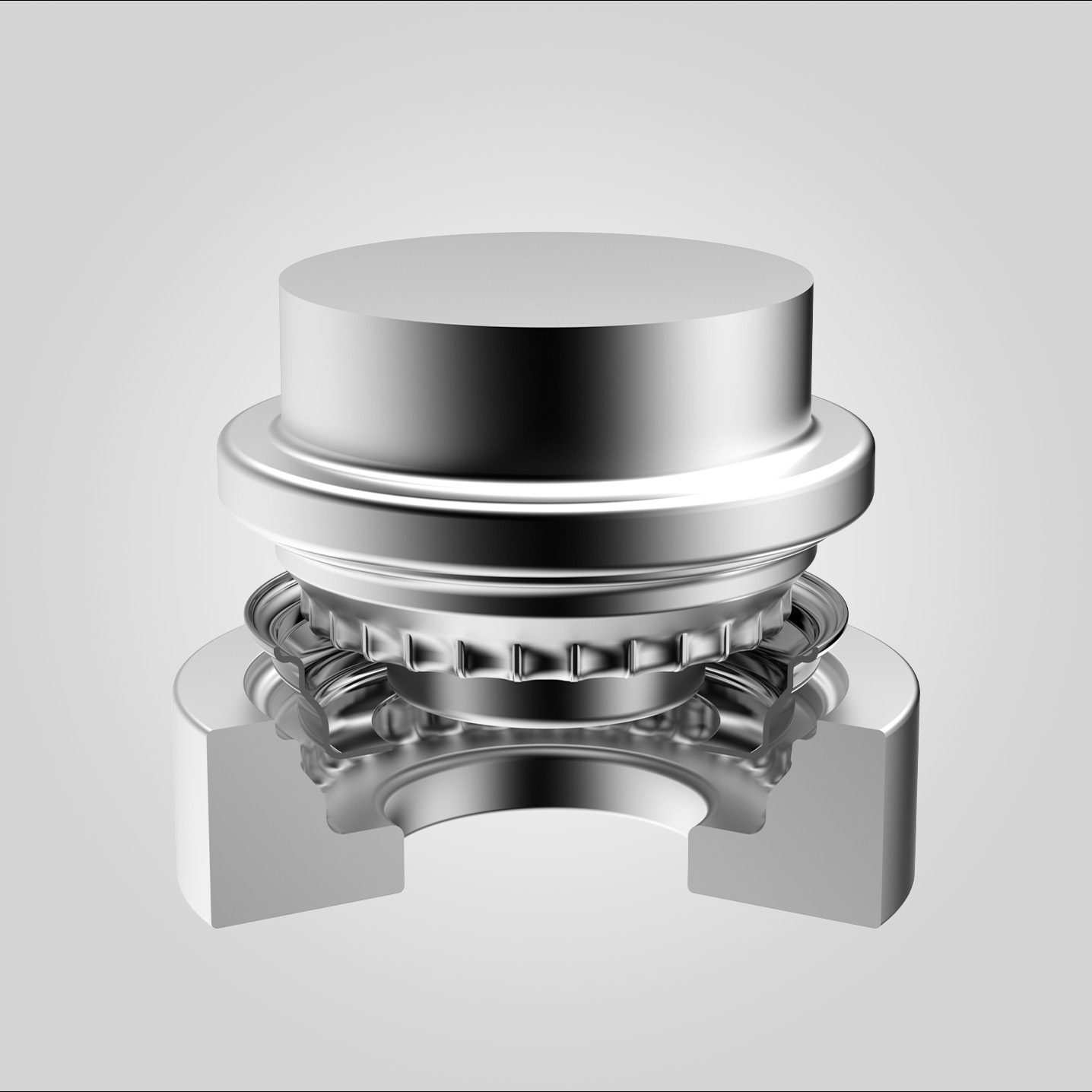

2 PIECE FORGED CONSTRUCTION

We’ve revolutionized our wheel construction with a new, stronger assembly method. This innovative design optimizes weight distribution and minimizes stress points, resulting in a wheel that’s built to endure and deliver lasting durability.

UPGRADED RIVETS

Our upgraded wheel assembly features high-strength rivets, engineered to enhance the wheel’s structural integrity. This translates to better performance, giving you the confidence and trust to push your ride further. The rivet width was upgraded from 8mm to 10mm. Simultaneously, we also increased the head of the rivet from 13mm to 16mm.